Sustainability

Since we began making socks in 2008, we’ve made it a priority to make decisions in the best interest of our planet.

At Sockwell, Sustainability & Concern for Our Environment Never Goes Out of Style!

It seems humans today are finally starting to come to terms with the impact we’re having on the planet. Without significant changes to the way we behave and the decisions we make, we’ll be headed for some pretty extreme circumstances. While there is almost no way to reverse the trend in one fell swoop, every positive change that one makes, when combined with the positive changes of others, can grow to make a meaningful difference.

When we founded this company in 2008, we made it a priority to make decisions in the best interest of the planet. Whether it’s the materials we use, maintaining the most compact carbon footprint possible, or any other area of how we do business, we’re always keeping the needs of our planet in mind.

USA Wool:

The Natural Choice

We source our wool from humanely raised US sheep and process it right here in the USA. Our partners use state-of-the-art, environmentally friendly processes to wash and dye our yarns, and we do it with one of the smallest carbon footprints in the industry. And when the wool has served its useful life as part of your favorite pair of socks, it will biodegrade and leave behind no trace.

Responsible Yarn Dyeing

We’ve been lucky to have Meridian Specialty Yarn Group as our partner for dyeing all our body yarns here in the USA. Meridian is based in Valdese, NC, and they are an industry leader in dyed yarns. Just last year, they completed the construction of a brand-new state-of-the-art dyehouse, enabling them to use a process called low liquor ratio dyeing.

Low liquor ratio dyeing dramatically reduces the amount of water used in dyeing the yarn. Typically, the amount of water in the dye bath is cut in half compared to conventional dyeing equipment.

What does this mean in practical terms? The new Meridian plant is able to recognize a 66% reduction in the water used per gallon of product dyed. Power usage in gas and electricity are reduced by approximately 50%, and chemical usage is also reduced by approximately half. Clearly, these are significant improvements in moving towards a more environmentally responsible manner in the way we conduct our business.

Transitioning to Recycled Nylon

If you’ve ever looked at the content of your socks, you might have noticed a significant percentage of your sock is made of nylon, typically 25% to 35%. Nylon is an important component in a sock, providing the structure that holds the sock to together, as well as much of the sock’s stretch and recovery. Without it, your socks wouldn’t fit very well or last nearly as long. Unfortunately, nylon is also a petroleum-based product.

At Sockwell, we’re moving to a recycled nylon made from pre-consumer fiber waste called Repreve®. For every pound of Repreve® nylon we use, we’re conserving the equivalent of .6 gallons of gasoline. This not only eliminates waste that would otherwise be headed for a landfill—it also eliminates the need for the crude oil to make new fiber and the associated chemical process required to produce it. Plus, it’s made right here in the USA, so we further shrink our carbon footprint.

We hope to have 80% of our total nylon usage converted to recycled nylon by the end of 2026.

Sustainable Packaging

We’re committed to using fully recyclable packaging materials. Our hanger packs are made of recyclable and/or biodegradable paper stock and the associated plastic hook is recyclable as well. All packaging is labeled with appropriate How2Recycle labeling. Our paper stock and packaging are produced in North Carolina, which again help us keep a compact carbon footprint.

We ship products purchased from SockwellUSA.com in poly-mailer bags from EcoEnclose. They are made of 100% recycled content (50% post-consumer waste) and printed with environmentally friendly ink. The bags are fully recyclable, and they even have a secondary adhesive strip allowing you to reuse the mailer if you want. Plus, our poly bags are made right here in the USA.

USA wool, USA made. Small footprint, big impact.

From day one, we’ve consciously chosen to keep our carbon footprint as small as possible—rather than shipping our yarns and other components all over the world for the sake of knitting a sock.

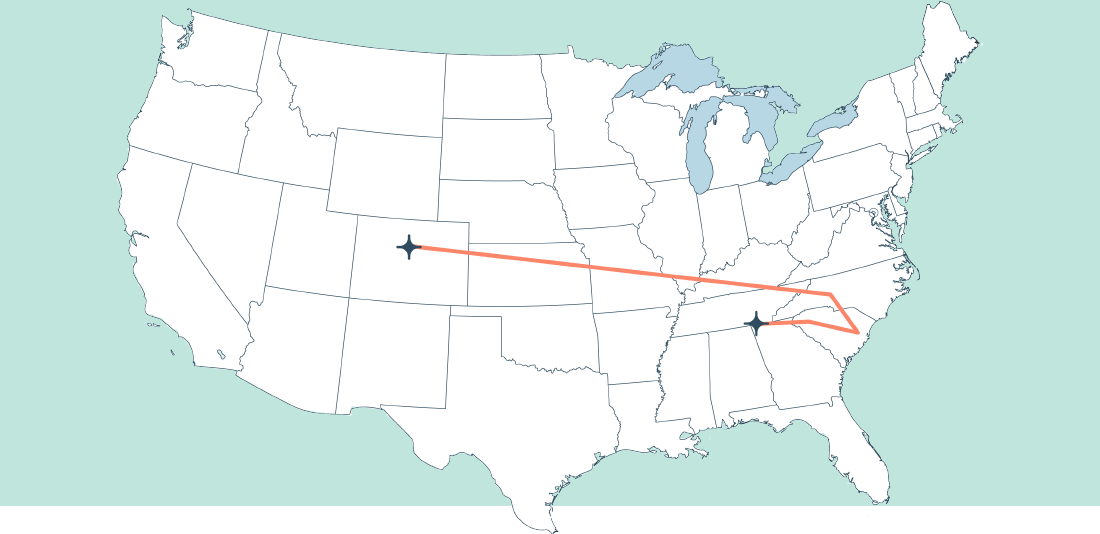

We source our wool, the primary ingredient in all of our products, from American wool producers. The raw wool is shipped to Jamestown, South Carolina where it’s scoured and shrink treated. From there, it travels to Pickens, SC to be spun into one of our custom crafted yarns. If the yarn requires dyeing, it travels to Valdese, NC. All of our socks are knit in Tennessee, North Carolina, and Alabama, and our packaging is printed in Concord, NC. The finished product is warehoused at our home base here in Chattanooga, TN. From here we ship our products across the US and around the world. If you’re here in the United States, you can feel proud that our wool doesn’t have to cross an ocean to find its way to your feet.

This is our trashcan & we’re proud of it.

When thinking about the way we run our business, we try to be mindful of waste at every level. Since we started in 2008, we’ve reused the cardboard boxes that our knitting mills ship product to our warehouse in to ship socks back out to our retail partners, dramatically reducing the amount of cardboard that would need to be recycled.

On top of that, we recycle all paper we use in our office and warehouse and all poly bags that we collect at the warehouse level. In fact, our 20-person office and warehouse staff generates less than a residential garbage can of landfill waste on a weekly basis.

Our Relentless Pursuit of Better Ways to Do Business

At Sockwell, we are never satisfied with the status quo. We’re always looking for a better way to do something. This includes our relentless quest to find ways to reduce our environmental impact and be better stewards of the planet.